Effective inspection of the flash welded joints with high capacity and inspection report

-

ultrasonic inspection of the weld joints along the rail section (including rail foot blades);

-

high efficiency (3-4 min. per 1 joint; up to 70 joints per shift);

-

108 inspection channels (00, 450, 580, 700)

-

automatic checking acoustic contact under all acoustic units;

-

system of prompts to operator by inspection stages;

-

recording GPS-coordinate of welded joint;

-

inspection protocol on each joint;

Modes of inspection weld joints:

-

availability of 5 acoustic units (on head and rail base point);

-

availability of 3 methods ultrasonic inspection (echo-, mirror, delta);

-

joint inspection for 4 stages: static – forward/back, scanning – forward/back;

-

providing results: defect on the rail image, A- and B – scan, parameters of setting flaw detector and detected defect;

-

analyzing results of scanning on B-scan with high and nominal sensitivity (-6 dB and 0 dB);

-

registration of the welded joint temperature;

-

detailed analysis of results on screen flaw detector or computer.

Display inspection results of weld joints:

-

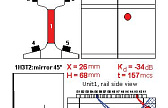

Static mode: ultrasonic inspection of the joint from two sides by mirror method

-

Scanning: ultrasonic inspection of the joint sides by echo-method

-

Possibility of clarify defect by manual probes