The latest model of intellectual flaw detector

-

new unit of inspection and indication CDU-31;

-

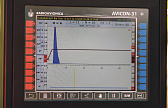

color display 8”;

-

touch control;

-

reliable digital communication;

-

GLONASS/GPS, Wi-Fi, GPRS;

-

microphone, video camera;

-

IP54, low level of power consumption;

-

new of ultrasonic multi-channel unit UMU-3204;

-

availability of 32 inspection channels;

-

several ultrasonic frequencies;

-

possibility to connect the scanner.

Innovation functions

Work preparation

-

Registration of the setting process by test unit (CO-3P);

-

Check up of probe’s efficiency;

-

Several ultrasonic inspection schemes;

-

Improved frame (by 11 points) and increased reliability of elements and units;

-

Connect of sliding systems and wheel inspection systems.

Searching defects

-

Big color display with possibility signals decoding on-route;

-

Automatic signal decoding on-route and reporting to operator;

-

Magnification of signals in mode “Bolt hole”;

-

Automatic increasing of sensitivity in bolted joint zone;

-

Inspection of defects under the rail surface and evaluation of damage’s sizes using special scanner;

-

Manual transducers 2.5 and 5 MHz.

Technologies performance

-

Possibility of quality record due to constant monitoring of signals on B-scan;

-

Quality evaluation of flaw detector settings directly during inspection (by regular reflectors);

-

Operator warning of approaching flaw section (preliminary transfer from database);

-

Inspection of acoustic contact under each probes;

-

Recording GPS-coordinate;

-

Registration of inspection speed

-

Registration of air temperature.

Decrypting

-

Recording of the separate photos, videos, and signal comments with linking to track coordinate;

-

Automatic decrypting;

-

Automatic searching of not inspected sections;

-

Possibility of data transmission using network operators;

-

Wireless data transfer as well from track line;

-

From -12 dB to +18dB - signal registration concerning to operating.