Designed for:

-

manual confirmed testing of the separate sections and welded joints by manual probe;

-

detecting internal defects in the railhead under surface damages using special scanner;

-

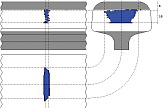

building-up of 3D defected railhead image;

-

monitoring of defected rails.

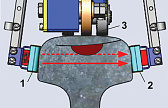

Reliable detection internal defects in the railhead under surface damages:

-

careful scanning of the rail head from sides by layers during 5min;

-

automatic sensitivity adjustment;

-

determination of real sizes and configuration of internal defects in railhead;

-

monitoring of defecting rails with an inspection report;

-

prolongation of the rail operation life.

Inspection by manual probes (0, 45, 50, 58, 65, 70) with registration:

-

welded rail joints;

-

separate rail sections according to removable and portable NDT;

-

display signal: A-scan or B-scan;

-

inspection report.