Effective inspection of rails with unsatisfactory surfaces in mode “Defectograms decryption” on speed of up to 5 kmh.

The best flaw detector among analogs of detecting defects: 19 defects/1000 km

-

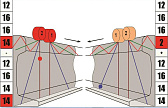

28 channels of ultrasonic scheme (0, 42, 58, 70);

-

possibility of switching wheel probes (summer time) and sliding probes (winter time);

-

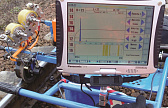

large color touch-sensitive screen;

-

total control of rails in mode “Defectograms derypting” on higher sensitivity or in common mode “Mnemonics”;

-

7 manual inspection channels (with manual transducers);

-

real-time display B-scan by all channels, A+B scan by one channel, with graphical defect position display (mnemonics), A-scan;

-

the technical solutions are protected by 7 patents;

-

stable acoustic contact on different types of the rails (rough, surface defects, worn out railhead, corrosion, joint steps);

-

reliable inspection of the bolted joints zones (crack detection in bolt holes which is not available for other flaw detection units);

-

deficiency of mechanical wear transducers inside wheel: stable control parameters, not required often calibration, long life time expectancy;

-

supplied with two types of ultrasonic inspection system (sliding and rolling), two batteries, spare parts and accessories, sample for setting.